Suspended Concrete Floors SNG Engineers Brisbane Gold Coast

Suspended beam and block floors have been in regular use, particularly for low-rise residential buildings, for many years, originally incorporating load-bearing concrete blocks between the prestressed beams, but more recently incorporating insulating materials (EPS), which were first introduced to the UK market some 25 years ago.

how to build a house framing Google Search Concrete floors

1. Solid Floating Concrete Ground Floor Slab A solid floating concrete ground floor slab should only be used if the depth of granular fill is less than 900mm. Diagram B51 - Typical detail of solid floating concrete ground floor slab 2. Cast In-Situ Suspended Ground Floor Slab.

Building Guidelines Drawings. Section B Concrete Construction in 2022

6 months ago Favourite Suspended floors are usually either made of timber or concrete with steel elements. Find out how they're made and what to watch out for on site. In this article we cover: What is a suspended floor? Suspended floors using structural concrete, from reinforced precast to ribbed Suspended ground floors using structural timber

Suspended Floors ThermoHouse

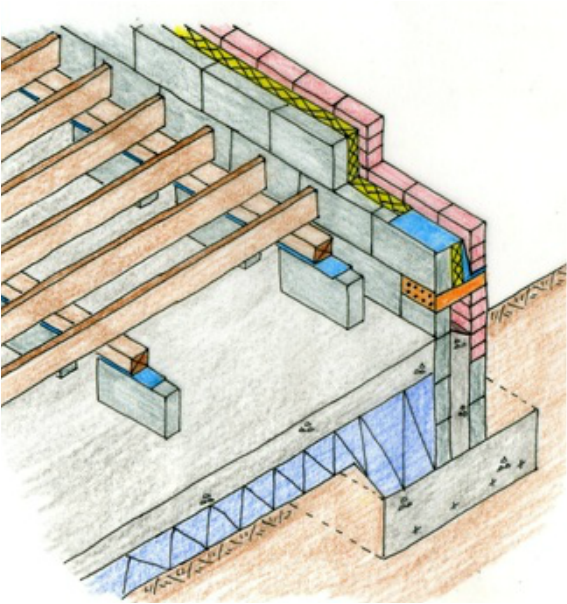

A suspended concrete floor is a floor slab where its perimeter is, or at least two of its opposite edges are, supported on walls, beams or columns that carry its self weight and imposed loading. The floor spans between supports and will normally deflect under load to a dimension that is limited by the design used.

P1PCFF3 Suspended Concrete Floor, Insulation Below Slab LABC

Diagram HC12 - Suspended timber ground floor - Extract from TGD C. Suspended Concrete Ground Floors. Suspended Concrete Ground Floor with Ventilated Voids. Suspended concrete ground floors should be constructed in-situ or using precast concrete a minimum of 100mm thick, the structural design however will determine the actual required thickness..

Suspended Floors ThermoHouse

HOW TO BUILD A SUSPENDED SLAB PART 1: EPISODE 5 In this video I show you how to build suspended concrete slab formwork for a 2 storey modern concrete house construction. The two storey.

Suspended Concrete Flooring Speedfloor

Curing Concrete and Remove Formwork 1. Assemble and Erect Formwork for Slab The formwork shall be designed to withstand construction loads such as fresh concrete pressure and weight of workers and operators and their machines. Guide to Formwork for Concrete ACI 347-04 shall be followed for the design of formworks.

A Best Practice Approach To Insulating Suspended Timber Floors

Suspended Concrete Slab. Suspended concrete slab is referred to a cement slab that is not in contact with the ground. This type of concrete slab construction requires different concrete slab design from the one we normally see that is cast on the ground. The most common application of suspended slab in residential construction is used at garage floor where below the garage floor is a storage.

Insulating Suspended Wooden Floors Wooden flooring, Underfloor

The recommended minimum reinforcement for concrete block construction is as follows: 4-½" diameter bars at corners vertically. 2-½" diameter bars at junctions vertically. 2-½" diameter bars at jambs of doors and windows for horizontal wall reinforcement use "Dur-o-waL (or similar) or ¼" bars every other course as follows:

Formezy Concrete Suspended Slabs

Suspended Floors Existing Concrete Slab 36. Concrete Slab On or Beow Gradl e. Dual-Sensing Thermostat Wiring Diagrams 61. Copper Manifold Dimeniosns 62. Floor Covering Transition Details 63. De˚nitions 65. CSI Recommended Speci˚cations WIRING Chapter 7 SYSTEM START-UP Chapter 8

Types Of Suspended Timber Floors Floor Matttroy

Stage 1. Determination of the calculated length of the slab. The actual length of the slab can be anything, but the calculated length, in other words, the beam's span (and in our case, the floor slab), is an entirely different matter. Span is the distance in the light between the load-bearing walls.

Patent US6755001 Suspended concrete flooring system and method

Here are my 5 most important things to check when inspecting a suspended concrete slab: 1. Reinforcement at Maximum Moment. At the most basic level, you are checking that the reinforcement is placed in the suspended slab in accordance with the design engineer's plans. That is the minimum standard and you should be aiming for better than that.

Suspended Floors ThermoHouse

Concrete suspended floors are made up of reinforced concrete beams which are dry laid on the damp-proof course on the inner skin of the external cavity walls. The beam manufacturer provides drawings showing the pattern of where the beams are to be positioned.

E5MCFF31 Suspended InSitu Concrete Floor, Insulation Below Slab LABC

Suspended concrete floor construction is increasingly the most common flooring system specified in residential construction. When selecting a floor construction there are a number of functional requirements that need to be considered. These include: Durability Strength and stability Resistance to ground moisture Fire safety

Patent US6755001 Suspended concrete flooring system and method

Concrete formwork - Acrow "V" shore. "U" screw jacks at the top support heavy timbers which in turn support joists for play. Concrete formwork - Square plated screw jacks at bottom, nailed to timber sole plates. These under all of the steel support legs and props. On the right is the slab formwork for a suspended concrete slab to a multi story.

Patent US6755001 Suspended concrete flooring system and method

Most ACI standards and committee reports are gathered together in the annually revised ACI Manual of Concrete Practice (MCP). American Concrete Institute 38800 Country Club Drive Farmington Hills, MI 48331 Phone: +1.248.848.3700 Fax: +1.248.848.3701. www.concrete.org.